WBCD 2026 Competition Track

Track 1: Logistics Picking

Robot from UnitreeRobot Demonstration

Teleop real robot video from Unitree—bring your best and do even better!

Many modern tasks are now performed using both arms and hands, incorporating various human perception systems and robotic hardware. However, current research typically relies on self-designed tasks and evaluations, often overlooking critical industry metrics such as operational speed, system reliability, and cost-effectiveness. To bridge this gap between research and practical application, the competition introduces a set of standardized benchmark tasks, aiming to foster collaboration between researchers and industry professionals in developing practical solutions to real-world challenges.

During the competition, participants may employ various methods to perform challenging maneuvers. The competition primarily evaluates the quality of task completion.

Task: Picking in Logistics Scenarios

This challenge simulates a logistics scenario where robots must transfer items from high shelves (Robot in upright position), low shelves (Robot in bent position), and ground shelves (Robot in crouched position) to a transport vehicle in the unloading area within a fixed time limit. There is no limit on the number of items transferred per operation, but items must be prevented from falling to the ground.

End effectors: A pair of end effectors (clamps, three-finger or five-finger dexterous hands)

Control method: VR headset or inertial motion capture suit

Human Demonstration

Sample task execution by a human operator for demonstration purposes.

Evaluation Criteria: I. Time Efficiency

- Complete most item transfer tasks within the specified time.

- Minimum time required to complete a single item transfer

Evaluation Criteria: II. Quality Standard

- Success rate of grabbing items from shelves

- Number of drops during robot transportation

Track 2: Logistics Packing Challenge

Robot from GalaxeaThis challenge focuses purely on stationary packing. It simulates a clean packing scenario where the robot needs to efficiently transfer items from a moving conveyor system to designated packing containers. The task involves picking items from 10 moving bins on a conveyor belt and organizing them in a target packing bin.

Picking Environment

- 10 picking bins move along conveyor at controlled speed

- Each bin contains identical items

- Items vary between bins (shape, size, weight)

- Time limit per bin at picking point

Packing Options

Uses rigid plastic container as packing bin

Advanced Version

Uses cardboard box with additional box closure requirement

Time Efficiency

- Total picking time (cumulative for 10 items)

- Total packing time (cumulative for 10 placements)

Quality Standards

- Items stacked tightly and neatly, not exceeding bin height

- For advanced version, cardboard box must be properly sealed

Sample Test Scene

Track 3: Life Science R&D - Lab Experiments

Robot from AgileX RoboticsThis year's Lab Experiments track simulates a real laboratory automation workflow: handling high-density sample racks, interfacing with an automated analytical instrument, and performing basic solvent/reagent operations (caps + flexible tubing).

The full task is organized into three steps. Teams are evaluated on successful execution, precision/safety (no damage, no collisions/spills), and operational efficiency.

Step 1: Sample Loading & Seating

Description: The robot must pick test samples from a bulk container or an array tray and accurately insert them into a high-density sample rack.

Success: Test samples are seated tightly in place.

Step 2: Instrument Interfacing

Description: Select specified samples from a full sample plate/tray and transfer them into a new tray.

Success: Correct samples are handled and placed as required, with safe/consistent interaction at the instrument interface.

Step 3: Mobile Phase Management

Description: Perform loosening and tightening of threaded caps on solvent bottles (Reagent Bottles A & B) and relocate flexible tubing.

Success: Flexible tubing is switched to the new target position, and bottles are tightened properly.

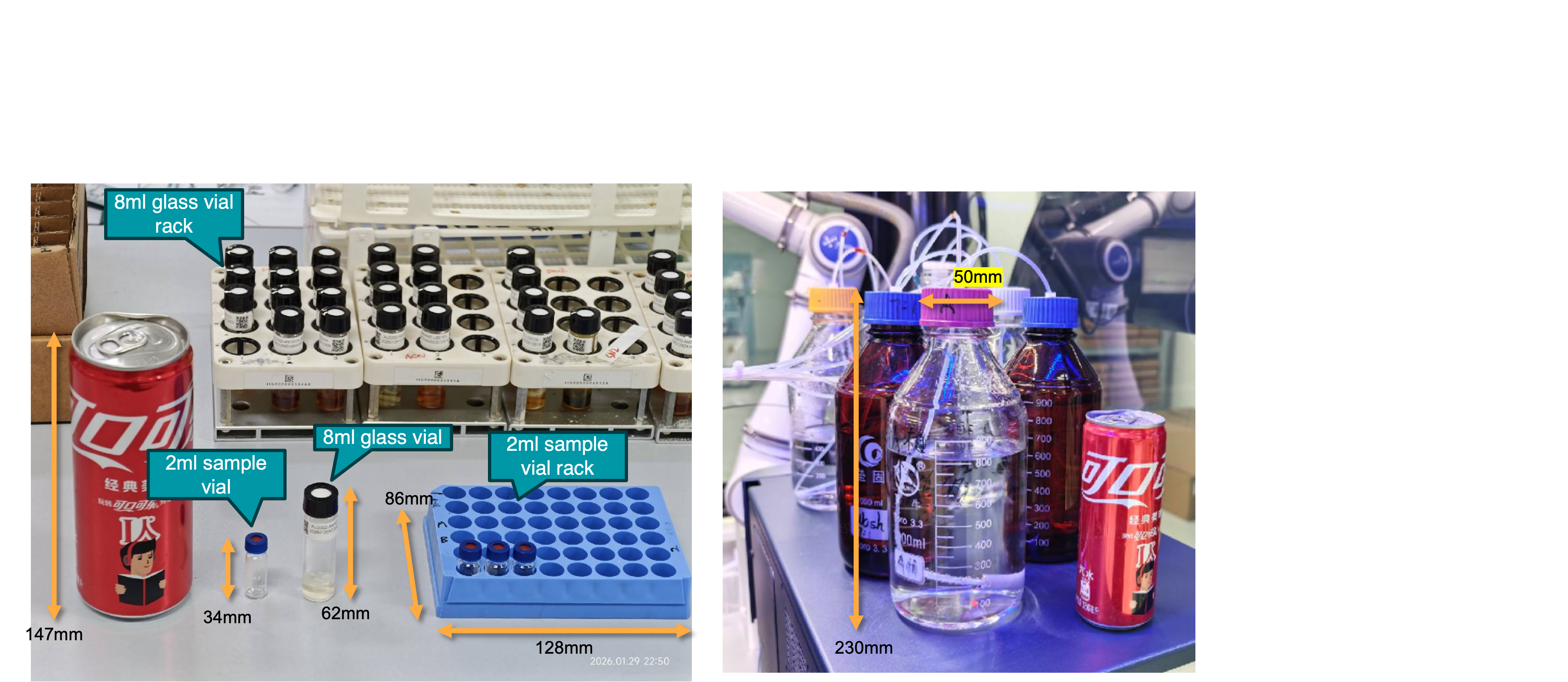

Consumables & Reference Dimensions

Track 4: Deformable Object Manipulation

Robot from ARXThis challenge evaluates robotic manipulation of deformable objects in manufacturing and service scenarios. Using a T-shirt as the representative flexible object, teams must demonstrate sophisticated perception and control capabilities.

Load T-shirt

Pick up and position the T-shirt into the workspace for manipulation.

Unload T-shirt

Remove the T-shirt from the workspace after manipulation is complete.

Fold T-shirt

Fold the T-shirt into a neat and consistent configuration.

Core Skills Assessed

- Perception and tracking of deformable objects

- Compliant grasping and manipulation

- Control of object deformation and alignment

- Consistency and quality of the final folded result