Overview

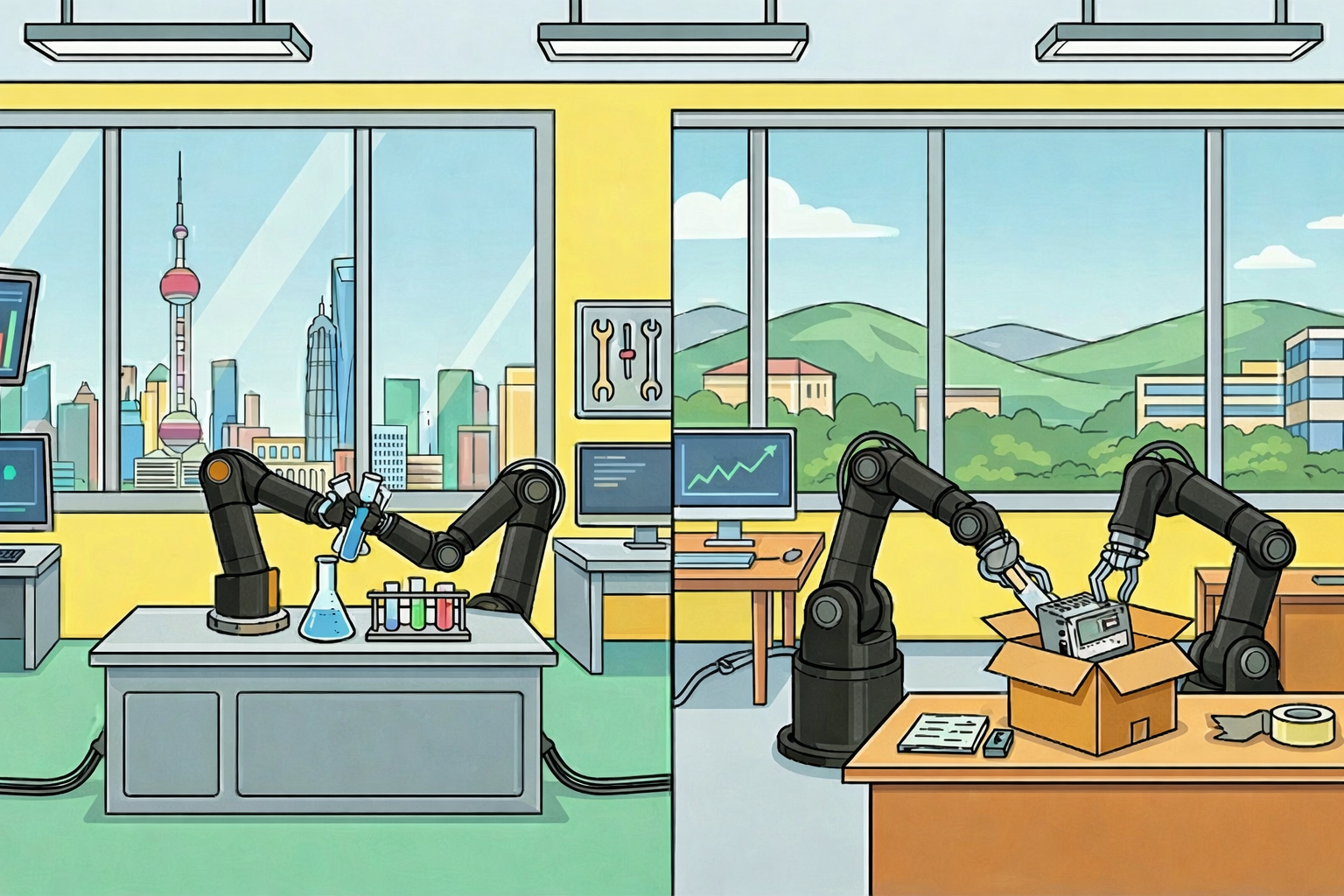

The WBCD Competition challenges teams to solve real-world manipulation tasks that represent actual industry needs with billion-dollar market potential. Unlike typical research benchmarks, our tasks are carefully designed by leading robotics companies to address genuine commercial applications in logistics, life sciences, and manufacturing.

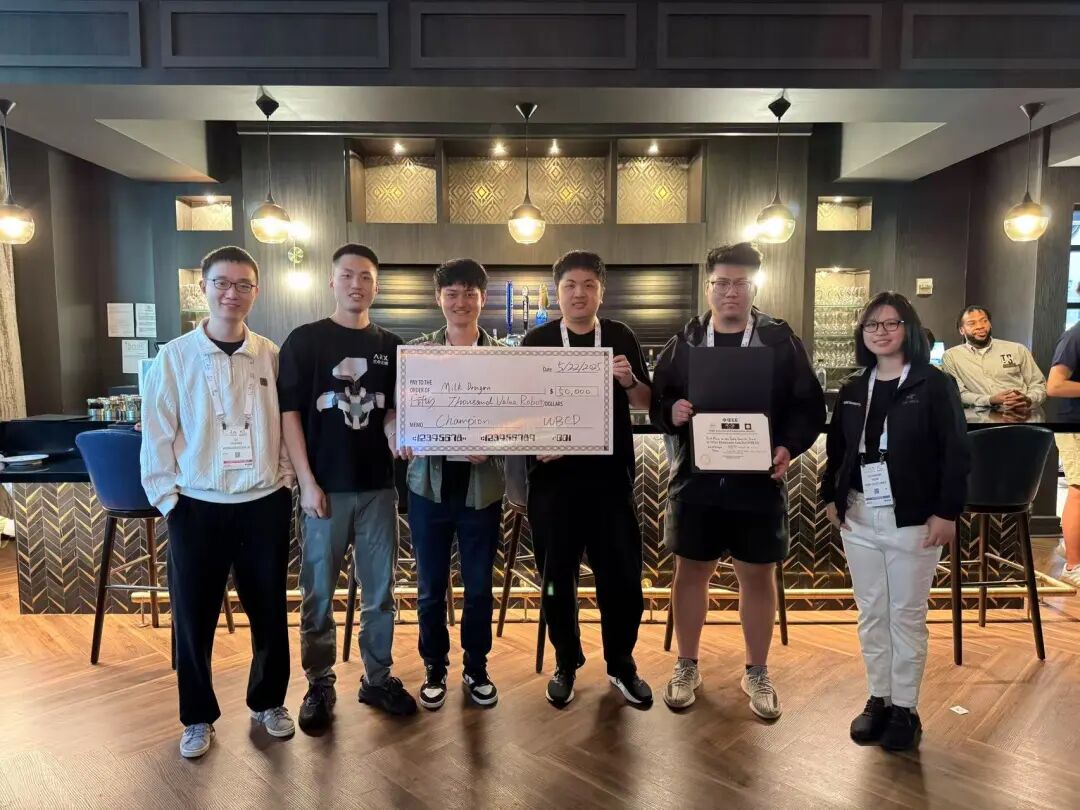

Compete for a $200,000 total prize pool, with first-place winners receiving a competition robot worth $50,000-$60,000. Teams will use bimanual teleoperation systems to complete complex tasks requiring coordinated dual-arm manipulation—a critical capability for next-generation automation.

Competition Tracks

Click on each track to explore detailed task descriptions and evaluation criteria.

Competition Format & Schedule

Key Dates

Competition Phases

Before Competition

At Competition

Awards

Track 1: Logistics Packing

Track 2: Lab Experiments

Track 3: Deformable Manipulation

WBCD 2025 Highlights

Highlights Gallery

What People Said About WBCD 2025

"My motivation for supporting this competition is simple: just to encourage these young people to dare to think, dare to try, and to ensure they have the opportunity to persist in their efforts."- Zhang Yan, CEO of DataWiz

"This competition made us realize that robotics breakthroughs require both hardware reliability and algorithmic robustness. Every detail, from motor control parameters to inverse kinematics, can be critical."- EPFL Create Lab Team, Winner of Life Science Track

"We didn't choose simple 'pick and place' tasks. We chose flexible objects and bimanual coordination to define the direction for academia and industry over the next 1-2 years."- Josh, CEO of ARX

"It was a delightful experience; I met so many passionate people and learned a lot too. Thank you for organizing it."- Vismay Vakharia, Tata Consultancy Services (TCS)

"My goal is to make it really easy for anyone to set up their own robot... just connect via a VR headset and get a first-person feel for it. I'm just here to see what everyone else is building and have a good time!"- Davide Heydt (Spawn), Solo Participant & Platform Developer

"We were constantly debugging, collecting data, and training policies for three days straight. We were exhausted, but the moment we learned we won the championship, all the fatigue vanished."- Li Weize, Team Nailong (Joint team from Tsinghua, NWU, Gatech, Umich), Winner of Table Operations

"We see a trend where teams are mixing teleoperation with end-to-end models to create a 'data flywheel.' It's a paradigm shift in the robotics industry, and it is very exciting."- Huang Di, WorldEngine AI

Organizers

Zhuo Xu

Research Scientist, Google Deepmind

Lingfeng Sun

Research Scientist, Robotics and AI Institute

Dennis Gu

General Manager of WBCD Competition

Peter Yu

CTO, XYZ Robotics

Yao Mu (Mark)

Assistant Professor, AI Institute, Shanghai Jiao Tong University

Huazhe Xu (Harry)

Assistant Professor, Tsinghua University

Michael Cho

Founder, Frodobots Lab

Danfei Xu

Assistant Professor, Georgia Tech

Weize Li

PhD Student, Clemson University

Tao Chen

CEO, Dexmate

Toru Lin

PhD Candidate, UC Berkeley

Di Huang

CEO, World Engine AI

Tianxing Chen

PhD Student, HKU

Kaifeng Zhang

PhD student, Columbia University

Max Yin

CEO at CyberOrigin

Calvin Zhou

Co-Founder at RoboForce

Wenhao Yu

Staff Research Scientist, Google Deepmind

Joseph J. Lim

Associate Professor, KAIST

Xinghao Zhu

Researcher, NVIDIA

Xiaohan Zhang

Research Scientist, Robotics and AI Institute

Hongyu Li

Ph.D. candidate, Brown University

Shihan Lu

Postdoctoral Researcher, Northwestern University

Paul HungHon Cheng

Postdoctoral Researcher, EPFL

Qinghua Guan

Postdoctoral Researcher, EPFL

Cheng Pan

Ph.D. Candidate, EPFL

Yang Ning

Senior System Engineer, ByteDance

Zhigen Zhao

PhD Candidate, Georgia Tech

Meiding He

Deep Tech Journalist

Yijia Yang

MBA Candidate at MIT Sloan

Charlie Cheng

Researcher at UC Berkeley

Xiatao Sun

PhD Candidate, Yale University

Yuhang Zheng

PhD Student, NUS

Zhengxiao Han

Researcher, Northwestern University